What You Need to Know About…Bearing Edges

This article originally ran in the Sept/Oct 2013 issue of Drum Business.

Many drummers don’t think about the edges of drum shells in terms of their impact on sound, but they can actually change the timbre quite dramatically. Therefore it’s a good idea to have a handle on different bearing-edge options and how they’ll affect the sound, in order to choose the most appropriate gear for your needs. Also, knowing the general history of how bearing edges have evolved over the last century can help you associate various drum design options with specific sounds and time periods in order to pinpoint exactly what you’re looking for.

Types of Bearing Edges

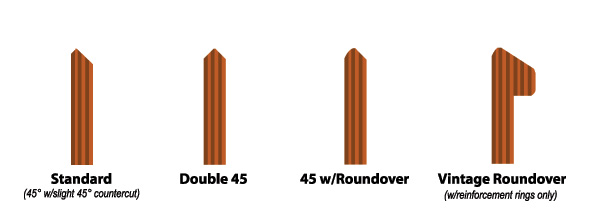

45-degree. This very common cut features a sharp 1-ply-thick edge that peaks close to the outside of the shell. Sharper bearing edges produce more attack and more sustain, which results in a generally more lively, “modern” sound. The added attack and sustain are due to less of the drumhead film being in contact with the shell.

A sharp 45-degree edge also produces considerably more harmonic overtones, which makes the drum sound brighter. These added overtones make tuning a bit more challenging, due to the shell’s increased sensitivity to minute changes in tension. Advertisement

Dual 45-degree. This design differs from a standard 45-degree edge in that the peak is moved to the center of the shell and has equal 45-degree cuts made from the inner and outer sides. The difference in sound comes from where the drumhead film contacts the bearing edge. Rather than contacting the head at the collar, which is the part of the head that curves down toward the hoop, a dual edge will meet the head further toward the center, where the film is flat. This results in longer sustain and a wider tuning range.

Roundover. This type of bearing edge is rounded off at the peak, resulting in more head-to-shell contact. Roundover bearing edges were the standard cut until the trend shifted toward sharper edges in the 1980s. Still utilized on many jazz and vintage-style drums today, roundovers tend to provide sharp stick impact and a mellower and warmer overall sound.

A drum will generally sustain a bit less with this type of bearing edge. There are also fewer harmonic overtones present, making for a meatier sound that features more of the fundamental pitch. Think of Ringo Starr or Ian Paice, or even modern players like Glenn Kotche of Wilco or Patrick Hallahan of My Morning Jacket, for examples of a warm roundover drum sound. Advertisement

Baseball bat or extreme roundover. This type of fully rounded edge was developed by industry giant Johnny Craviotto and is typically used on larger drums. The edge produces the fewest overtones and a fat, punchy sound. While certainly not for every drummer or every musical situation, this style of edge can create some beautiful, vintage-type sounds. The Craviotto Drum Company describes the design by saying, “The baseball bat edge is the ideal choice for drummers looking to replicate the warm tom and resonant bass drum sounds associated with the 1960s. This edge speaks beautifully in mid to low tuning ranges.”

Hybrid. The concept of combining different edges on the batter and resonant sides of drums is a new development in manufacturing. A common pairing would be a roundover edge on the batter side and a standard or dual 45-degree edge on the resonant side. This combination is often used on snare drums to harness the advantages of both types of edges in the same instrument. Some manufacturers are also using this concept because they believe it can maximize the performance of different drum sizes. Pearl’s Reference series, for example, utilizes different bearing edges, shell composition, and thickness as the sizes of the drums increase.

Additional Construction Considerations

Other aspects of a drum’s design will interact with different styles of bearing edges. Though the wood that a drum shell is made of has the most direct impact on the overall sound, bearing edges introduce another important variable into the equation. Common species, like maple, birch, mahogany, and oak, have aural characteristics that we’re all familiar with, but they’re most often cut with sharp bearing edges. What if you combine a long-sustaining wood like maple with a 30-degree roundover edge? This is where you can really start to dig into your customers’ needs. Be sure to ask about their favorite kinds of music, as well as their musical goals, in order to zero in on an ideal sound. Advertisement

Bearing edges are only one piece of the puzzle when choosing drums to fit certain applications. You’ll also want to consider factors like drum sizes, shell composition, ply configuration (horizontal, vertical, diagonal, etc.), hardware, mounting options, finish type (lacquer versus oil or wrap), and drumheads. Be prepared to experiment with a variety of options, and soon you’ll understand just how different types of bearing edges affect the sound of a drum.

And be sure to check out our other What You Need to Know About features here.